The importance of Good Documentation Practice (GDP) in the pharmaceutical industry

In the pharmaceutical industry, compliance with Good Documentation Practice (GDP) is crucial to ensure the quality, safety and efficacy of medicines. GDP refers to the accurate, consistent and timely documentation of all aspects of drug manufacturing and distribution. It is a fundamental requirement to ensure data integrity, fulfil regulatory requirements and ensure patient safety.

Why is GDP important?

Correct documentation plays a central role in the monitoring and control of manufacturing processes. It enables the traceability of raw materials, the manufacturing processes as well as the packaging and storage of medicinal products. This is crucial for recognising and rectifying quality deviations and coordinating recalls if necessary. In addition, thorough documentation serves as proof of compliance to regulatory authorities.

Key principles of GDP

- Accuracy: All information must be recorded accurately and correctly. Errors in documentation can lead to quality problems and jeopardise patient safety.

- Legibility: Documents must be clear and legible to avoid misunderstandings. Poor legibility can lead to misinterpretation and incorrect decisions.

- Traceability: It should be possible to trace every step of the manufacturing process and product distribution. This enables a quick response to quality problems and efficient tracing in the event of recalls.

- Timely documentation: All information must be documented in a timely manner and immediately after the event in order to have real-time data available.

GDP in practice

GDP compliance requires a clear documentation policy and procedures that must be followed by all employees. This includes staff training, regular document reviews, the use of approved templates and the regular updating of records.

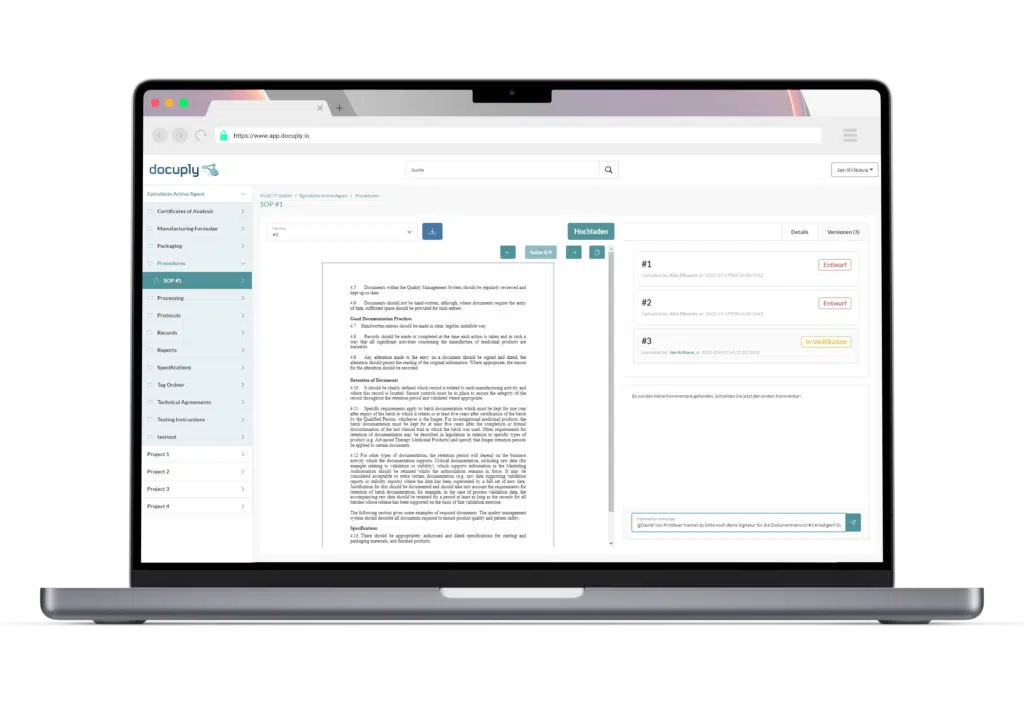

The use of modern technology and electronic documentation systems has improved the efficiency of GDP. These systems enable accurate data capture, storage and management, reduce human error and facilitate review by regulatory authorities.

Easily implement Good Documentation Practice with Docuply and streamline your document management.

The importance of GDP for patient safety

Ultimately, compliance with GDP helps to ensure that patients receive high-quality and safe medicines. Accurate documentation and monitoring throughout the manufacturing and distribution process minimises the risk of contamination, counterfeiting or other quality issues.

Conclusion

Good Documentation Practice is an indispensable pillar in the pharmaceutical industry. It not only ensures compliance with regulations, but also the safety and quality of medicinal products. Comprehensive and accurate documentation is therefore crucial to ensure the protection of patients and to strengthen trust in pharmaceutical companies and their products.

Note: This article is for information purposes only and does not replace professional advice in connection with GDP in the pharmaceutical industry.

Test all the advantages of a digital document management system specially developed for the pharmaceutical and biotech industry now, with no obligation. You can get started in just five minutes – convince yourself.

Quality management in the pharmaceutical and biotech industry: Current challenges in the collaboration between pharmaceutical companies and CROs, CMOs and CDMOs